Energy Recovery Wheels

AIRotor's air-to-air energy recovery wheels save you power and cost while helping sustain a greener planet.

AIRotor Series SXA—Energy Recovery Wheels

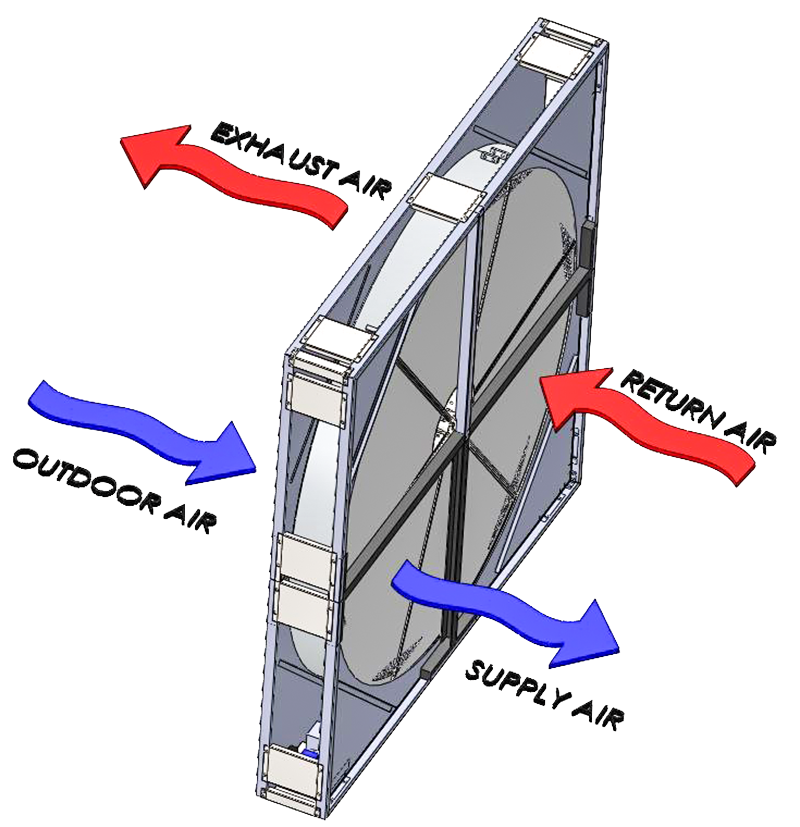

The Series SXA energy recovery wheels transfer the energy from one air path to the other but much differently than the cores. Instead of using cross-flow plates, the energy recovery wheels use core media to retain the energy as they rotate from one air path to the other.

AIRotor energy recovery wheels are available in Sensible Only (8” deep aluminum corrugated coil) or Latent Inclusive (additional hygroscopic molecular sieve 3A desiccant).

The energy core is constructed of corrugated aluminum and layered in a continuous coil.

Often referred to Enthalpy Energy Wheels, the media can be supplied with or without desiccant coating. By applying a permanently bonded 3A desiccant material to the media, the latent energy is transferred in addition to the sensible energy. The 3A-sized desiccant coating traps only the water molecules for transfer to the other air stream.

While the energy core is stationary, the energy wheel rotates. The media transfers temperature and humidity properties as it rotates from the return air / exhaust air path back around to the supply air path.

AIRotor Energy Recovery Wheel Features

- Sizes from Small to Large (2’ - 16’ Diameters)

- Air Flows from 1,000 to 100,000 CFM

- Performance Effectiveness up to 85%

- UL-1995 Standard: All wheels are tested for conformance and inspected to UL-1995 Standard

- ETL Listed

- AHRI Certified: Air-to-air ERV Certified Component to AHRI Standard 1060

AIRotor Energy Recovery Wheel Advantages

- Uniqueness among the competition in price, high-energy transfer, low-pressure drop, low cross-contamination, and minimum maintenance

- Value-engineered design in structure and drive with heavy-duty wheel construction allows for high face velocities of up to 1.1” wg pressure drop in non-sectioned, single-piece wheels and up to 1.3” wg pressure drop in all sectioned wheels

- Low to no cross-flow contamination: Double brush and blade seals on wheel faces and an adjustable purge up to 100 effectively eliminates rotational contaminant carryover

- Sectioned frame and wheel design allows the rotor and case to be assembled on-site facilitating easy transportation and installation

- Low RPM eliminates the need for frost control bypass

- Water does not condense on the desiccant-coated rotor therefore no drain pan is required Wheels are fully Assembled and Tested with Motor and Drive for very simple installation

- Variety of control and other options for special applications and specifications